1.Kakaretso

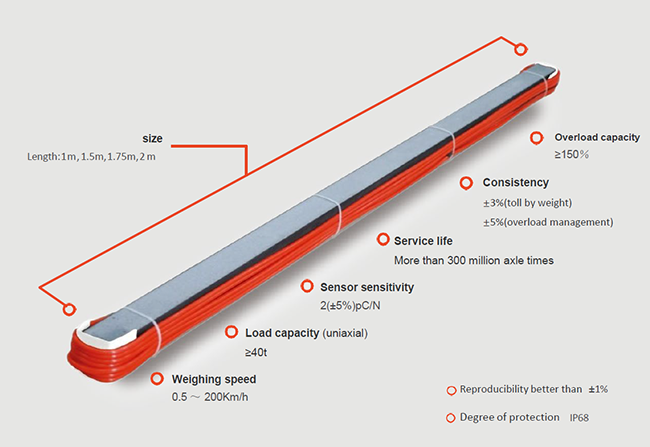

CET8312 Piezoelectric Quartz Dynamic Weighing Sensor e na le litšobotsi tsa mefuta e mengata ea ho lekanya, botsitso bo botle ba nako e telele, ho pheta-pheta hantle, ho nepahala ha tekanyo e phahameng le maqhubu a phahameng a ho arabela, kahoo e loketse ka ho khetheha bakeng sa ho lemoha boima bo matla. Ke sensor e thata, e matla ea ho bekha e thehiloeng holim'a molao-motheo oa piezoelectric le sebopeho se nang le tokelo ea molao. E entsoe ka letlapa la kristale ea quartz ea piezoelectric, poleiti ea electrode le sesebelisoa se khethehileng sa beam. E arotsoe ka 1-mithara, 1.5-mithara, 1.75-limithara, 2-limithara boholo litlhaloso, e ka kopantswe ka mefuta e fapaneng ya litekanyo tsa sephethephethe tseleng, ka ikamahanya le maemo a boima bo boima litlhoko tsa holim'a tsela.

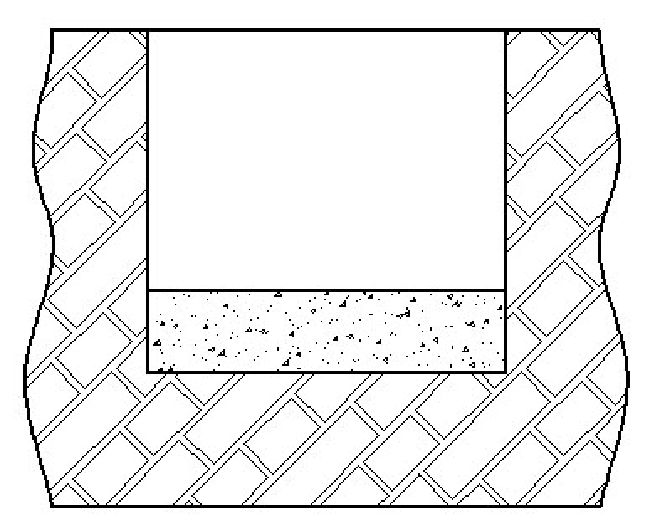

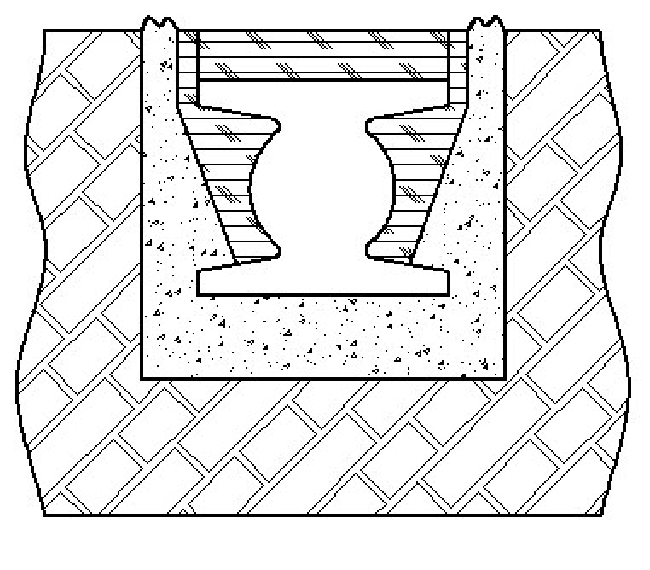

2.Setšoantšo sa CET8312

3.Technical Parameters

| Litekanyo tsa likarolo tse fapaneng | (48mm+58mm)*58 limilimithara | ||

| Bolelele ba Sensor | 1m/1.5m/1.75m/2m | ||

| Bolelele ba thapo | Ho tloha ho 25m ho isa ho 100m | ||

| Boima ba axle (e le 'ngoe) | ≤40 t | ||

| Bokhoni ba ho tlala | 150% FS | ||

| Boikutlo ba ho jara | 2±5%pC/N | ||

| Lebelo la lebelo | Ho tloha ho 0.5km/h ho isa ho 200km/h | ||

| Mophato wa tshireletso | IP68 | Boiphetetso ba sephetho | >1010Ω |

| Mocheso o sebetsang. | -45℃80℃ | Sephetho sa mocheso oa mocheso | <0.04%FS/℃ |

| Khokelo ea motlakase | High frequency static lerata coaxial cable | ||

| Bearing surface | Bearing surface e ka belisoa | ||

| Nonlinear | ≤± 2% FS (ho nepahala ha static calibration ea li-sensor sebakeng se seng le se seng) | ||

| Ho lumellana | ≤± 4% FS (ho nepahala ha static calibration ea lintlha tse fapaneng tsa boemo ba sensor) | ||

| Ho pheta-pheta | ≤± 2% FS (ho nepahala ha static calibration ea li-sensor sebakeng se le seng) | ||

| Ho mamellana ka nepo | ≤±5% | ||

4.Mokhoa oa ho kenya

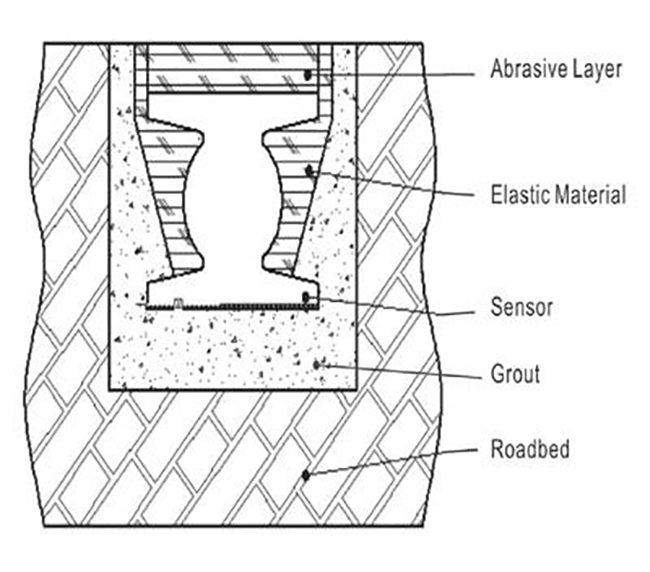

1) Kakaretso ea Sebopeho

E le ho netefatsa phello ea tlhahlobo ea ho kenngoa hohle ha sensor, khetho ea sebaka e lokela ho ba thata. Ho kgothaletswa hore ho be le samente e thata

tsela e katiloeng e lokela ho khethoa e le motheo oa ho kenya sensor, 'me tsela e bonolo e kang asphalt e lokela ho fetoloa. Ho seng joalo, ho nepahala ha tekanyo kapa bophelo ba tšebeletso ea sensor bo ka ameha.

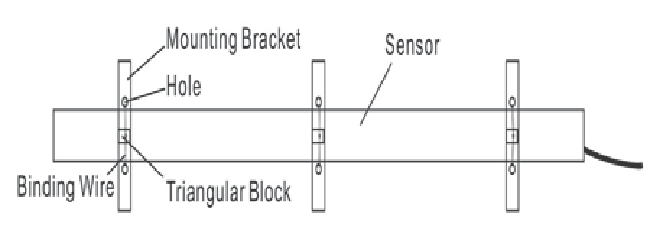

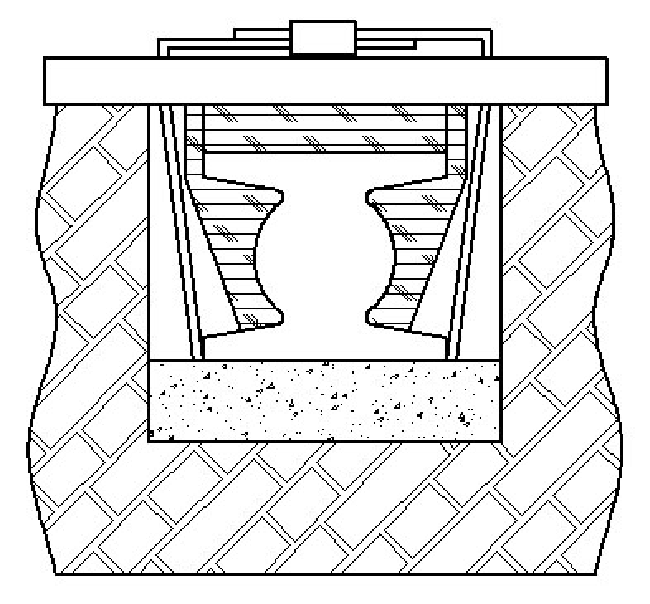

2) Bracket e ntseng e eketseha

Ka mor'a hore sebaka se behoe, sekontiri se nang le likoti tse fanoeng ka li-sensor se lokela ho ts'oaroa ho sensor e nang le tepi e telele ea terata, ebe ho sebelisoa lehong le lenyenyane la kgutlotharo ho kenya lekhalo pakeng tsa lebanta le tie-up le bracket e ntseng e phahama, e le hore e ka tiisoa. Haeba basebetsi ba lekane, mohato oa (2) le (3) o ka etsoa ka nako e le 'ngoe. Joalokaha ho bontšitsoe ka holimo.

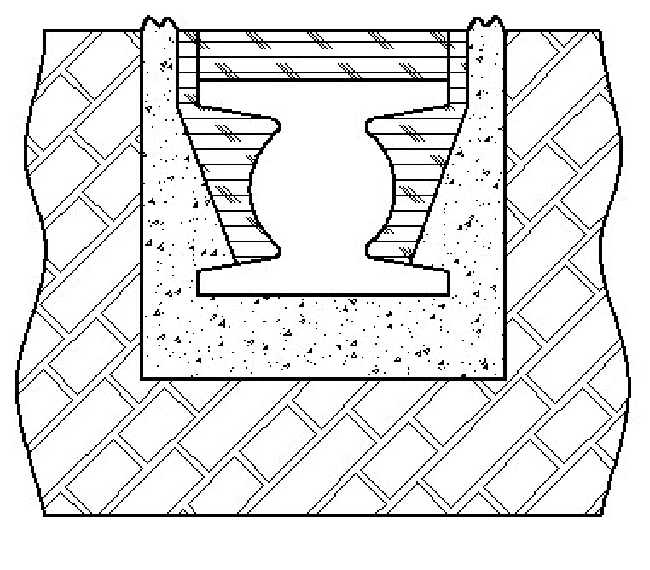

3)Pavement Grooving

Sebelisa rula kapa sesebelisoa se seng ho tseba hore na sensor e matla ea boima e eme hokae. Mochine oa ho itšeha o sebelisetsoa ho bula li-grooves tse nang le mahlakore a mabeli tseleng.

Haeba li-grooves li sa lekane 'me li na le likhahla tse nyenyane moeling oa li-grooves, bophara ba li-grooves ke 20 mm ho feta ea sensor, botebo ba li-grooves ke 20 mm ho feta ea sensor, le 50 mm e telele ho feta ea sensor. Li-cable groove li bophara ba 10 mm, botebo ba 50 mm;

Haeba li-grooves li entsoe ka hloko 'me lipheletsong tsa li-grooves li boreleli, bophara ba li-grooves ke 5-10mm ho feta ea li-sensor, botebo ba li-grooves ke 5-10mm ho feta li-sensor,' me bolelele ba li-grooves ke 20-50mm ho feta li-sensor. Li-cable groove li bophara ba 10 mm, botebo ba 50 mm.

Botlaaseng bo tla fokotsoa, silt le metsi ka har'a li-grooves li tla hlajoa li hloekile ka pompo ea moea (ho omisoa ka ho feletseng ho tlatsa grout), 'me karolo e ka holimo ea mahlakoreng ka bobeli a li-grooves e tla kenngoa ka tepi.

4) Nako ea pele ea Grouting

Bula grout ea ho kenya, ho ea ka karolo e behiloeng ho lokisa motsoako o tsoakiloeng, ka potlako ho kopanya grout le lisebelisoa, ebe o tšela ka ho lekana.

tataiso ea bolelele ba groove, ho tlatsoa ha pele ka har'a groove e lokela ho ba ka tlase ho 1/3 ea botebo ba groove.

5) Sensor Placement

Ka bonolo beha sensor ka bracket e ntseng e hola ka har'a slot e tletseng grout, lokisa bracket e ntseng e phahama 'me u etse hore fulcrum e' ngoe le e 'ngoe e ame bokaholimo ba slot,' me u netefatse hore sensor e bohareng ba slot. Ha li-sensor tse peli kapa ho feta li kenngoa ka har'a slot e le 'ngoe, tlhokomelo e khethehileng e lokela ho lefshoa karolong ea khokahanyo.

Sebaka se ka holimo sa li-sensor tse peli se tlameha ho ba boemong bo lekanang, 'me motsoako o tla ba o monyenyane ka hohle kamoo ho ka khonehang, ho seng joalo phoso ea tekanyo e tla bakoa. Boloka nako e ngata kamoo ho ka khonehang mohatong oa (4) le (5), kapa grout e tla phekola (lihora tse 1-2 tsa nako e tloaelehileng ea ho folisa ea sekhomaretsi sa rona).

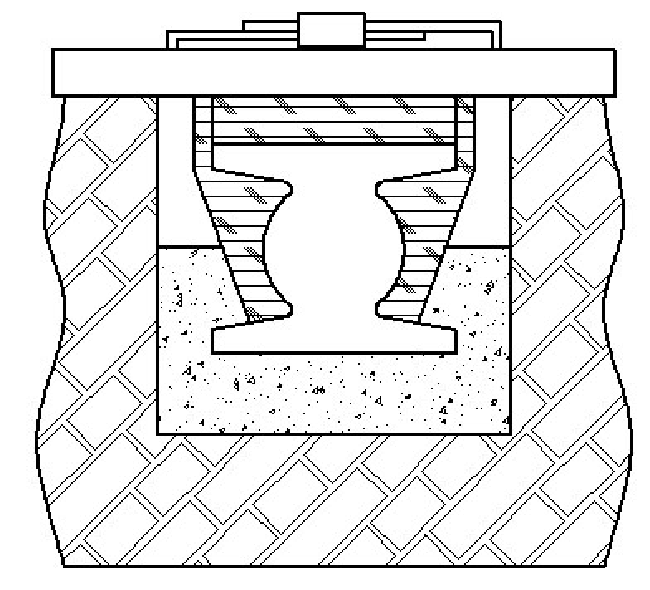

6) Ho tlosoa ha Mounting Bracket le Second Grouting

Ka mor'a hore grout e folisoe, sheba phello ea pele ea ho kenya sensor, 'me u e fetole ka nako ha ho hlokahala. Ntho e 'ngoe le e' ngoe e se e loketse, ebe u tlosa bracket, u tsoele pele ka grouting ea bobeli. Ente ena e lekanyelitsoe ho bophahamo ba holim'a sensor.

7) Nako ea Boraro ea Grouting

Nakong ea ho folisa, ela hloko ho eketsa palo ea grout ka nako leha e le efe, e le hore boemo bo akaretsang ba grout ka mor'a ho tlatsa bo phahame hanyenyane ho feta tsela.

8) Ho sila ka holim'a metsi

Ka mor'a hore li-grout tsohle tsa ho kenya li fihlele matla a ho folisa, khaola theipi, 'me u sila bokaholimo ba groove le holim'a tsela, etsa tlhahlobo ea preloading ka koloi e tloaelehileng kapa likoloi tse ling ho hlahloba hore na ho kenngoa ha sensor ho nepahetse.

Haeba tlhahlobo ea preloading e tloaelehile, ho kenya ke

phethiloe.

5.Litsebiso tsa ho Kenya

1) Ho thibetsoe ka thata ho sebelisa sensor ho feta moeli le mocheso o sebetsang ka nako e telele.

2) Ho thibetsoe ka thata ho lekanya ho hanyetsa ha sensor ea sensor e nang le mitha e phahameng ea ho hanyetsa ka holimo ho 1000V.

3) Basebetsi bao e seng litsebi ba thibetsoe ka thata ho e netefatsa.

4) Mokhoa oa ho lekanya o lokela ho lumellana le lisebelisoa tsa aluminium, ho seng joalo ho hlokahala litaelo tse khethehileng ha u laela.

5) Qetello ea tlhahiso ea sensor L5 / Q9 e lokela ho bolokoa e omme ebile e hloekile nakong ea tekanyo, ho seng joalo tlhahiso ea pontšo ha e tsitsa.

6) Sebaka sa khatello ea sensor se ke ke sa otloa ka sesebelisoa se hlabang kapa matla a boima.

7) Bandwidth ea amplifier ea tefiso e tla ba holimo ho feta ea sensor, ntle le hore ha ho na tlhoko e khethehileng ea karabelo ea khafetsa.

8) Ho kenngoa ha li-sensor ho lokela ho etsoa ho latela litlhoko tse nepahetseng tsa litaelo e le ho fihlela tekanyo e nepahetseng.

6.Liphutheloana

Buka ea 1 PCS

Ho tšoaneleha ha netefatso 1 PCS Certificate 1 PCS

Hangtag 1 PCS

Q9 thapo e hlahisoang ke 1 PCS

Enviko Technology Co.,Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ofisi ea Chengdu: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Hong Kong Office: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Nako ea poso: Aug-19-2024